10/26/20: Hatches, Ladder

Here is the hatch-end hinge hardware on one of the three hatches that require hinges. They are (1) the forward hatch that opens to the forward cabin/V-berth area, (2) the main hatch that opens to the main cabin area, and (3) the aft hatch that opens to the aft locker under the mizzen mast.

I need the vertical gaps between the hatches and the coamings to be even, so I taped some old gasket material to the inside of each hatch, all around.

There is a camber to the house so the house-end hardware required wedge-shaped pads. I modified and old scarf jig to cut the banks.

The wedge shape to the pads was actually an advantage, as I was able to achieve the correct height by simple moving them back and forth.

The coaming for the aft hatch was a little too high, so I built a box to be used as a router guide.

X

Here I’ve positioned the box at the correct height and screwed it to the inside of the coaming.

The router cannot get all the wait to the corners, so…

…and…

…then some work with a belt sander.

I cut the pads to length and used a bottle cap to trace rounded corners.

There are 8 pads in all, and I used the hinge parts as drilling templates, then rounded off the corners.

These pads will get no varnish, but they were sanded to remove any machine marks.

The 8 pads require 8 backing plates for under the house and aft deck.

A dry fit of starboard, deck-side hinge. Note that these pads are not wedge shaped, as the aft deck has no camber.

Here is a backing plate under the house. These will get three coats of varnish . These bolts will eventually be cut down so the ends of each of them are close to the nut.

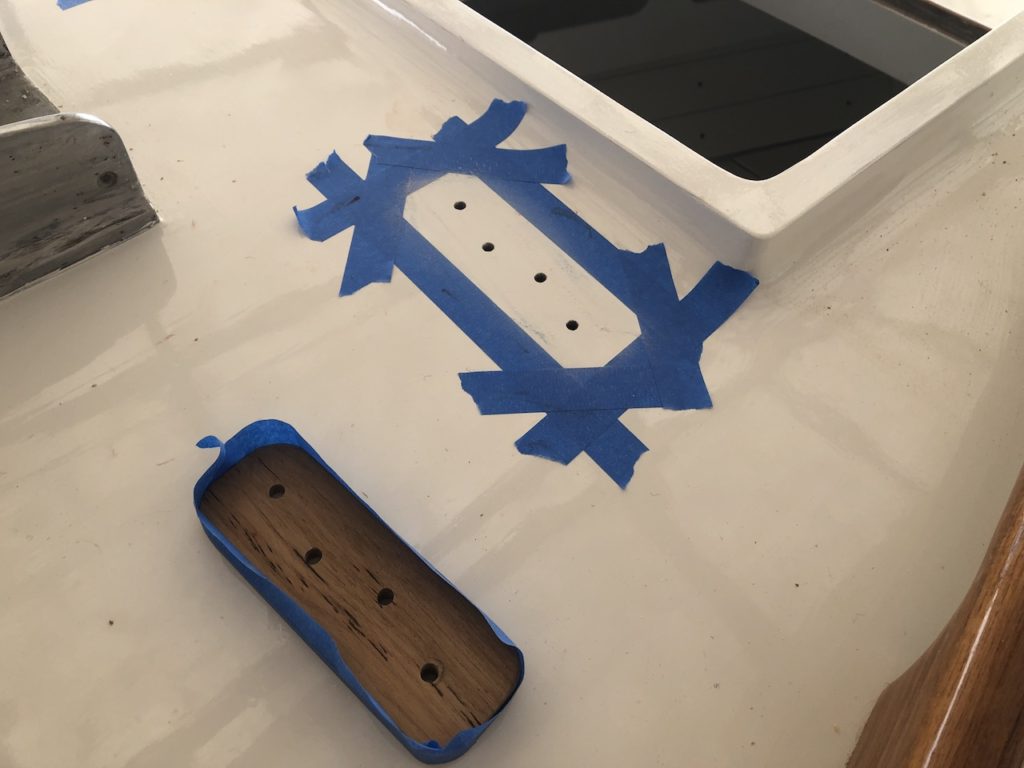

The tape on the house here is for containing the sanded area before final bonding.

This hardware is bonded with Sikaflex 291, black sealant.

Here is the forward hatch.

There’s still quite a bit to do with the hatches. Namely, gasket, locking mechanism, holding-open mechanism, as well as other issued that will be explained in a later post.

x

The main hatch has hinge hardware on both the forward and aft sides. In this way, the round bar can be moved to one side or the other, depending on how I want the hatch to lift.

The main hatch from the inside:

From this perspective you are lying on the port-side V-berth, looking up:

There will be more on hatches later.

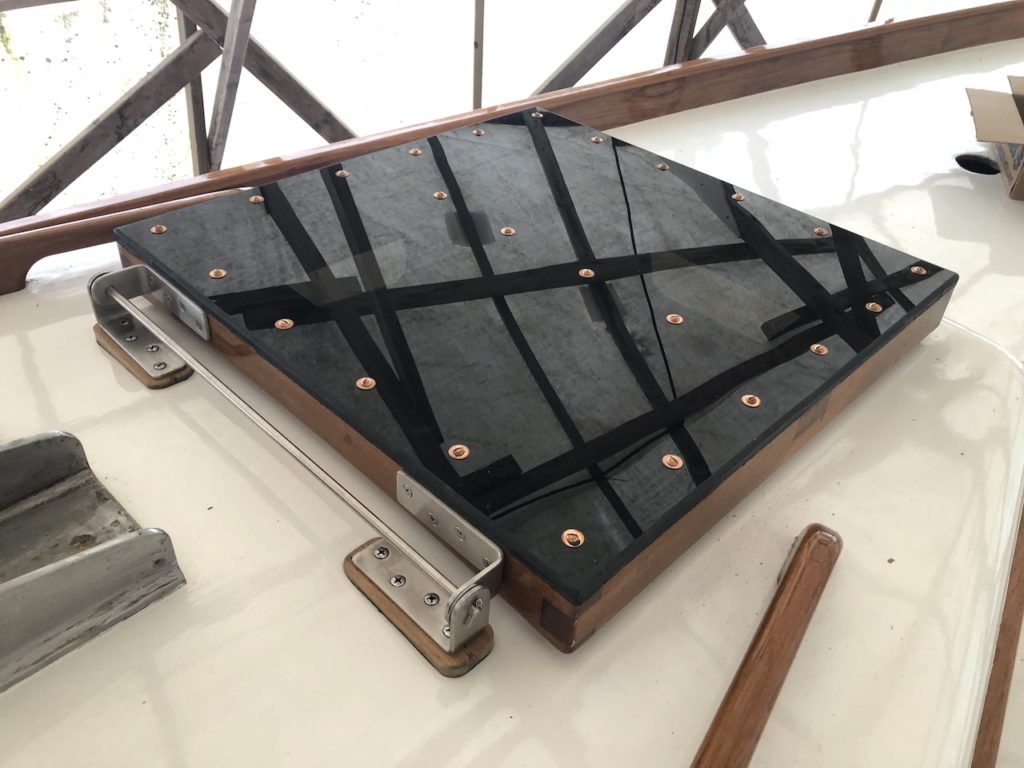

Meanwhile, I finished installing the companionway ladder hardware:

And finally, the cockpit was prepped, primed, and painted. I’ll retrieve the teak grates from storage and put them in on the sole sometime soon.

Mom

11/01/2020 — 9:11 pm

WOW! She is beautiful!!

Mike

11/15/2020 — 4:27 pm

Thanks Mom!

Bill

11/01/2020 — 10:18 pm

Hi Mike,

Your work sure looks great ! You should get the pics & description in a book.

I am certain that with the right title and these photos and Your description anyone that has any interest in boats would buy a copy . Especially owners of ChoyLee sailboats and anyone interested in restoring some other hull from another manufacturer.

Bill Heagney

Mike

11/15/2020 — 4:27 pm

Thanks Bill!