9/19/20: Painting, Grab Rails

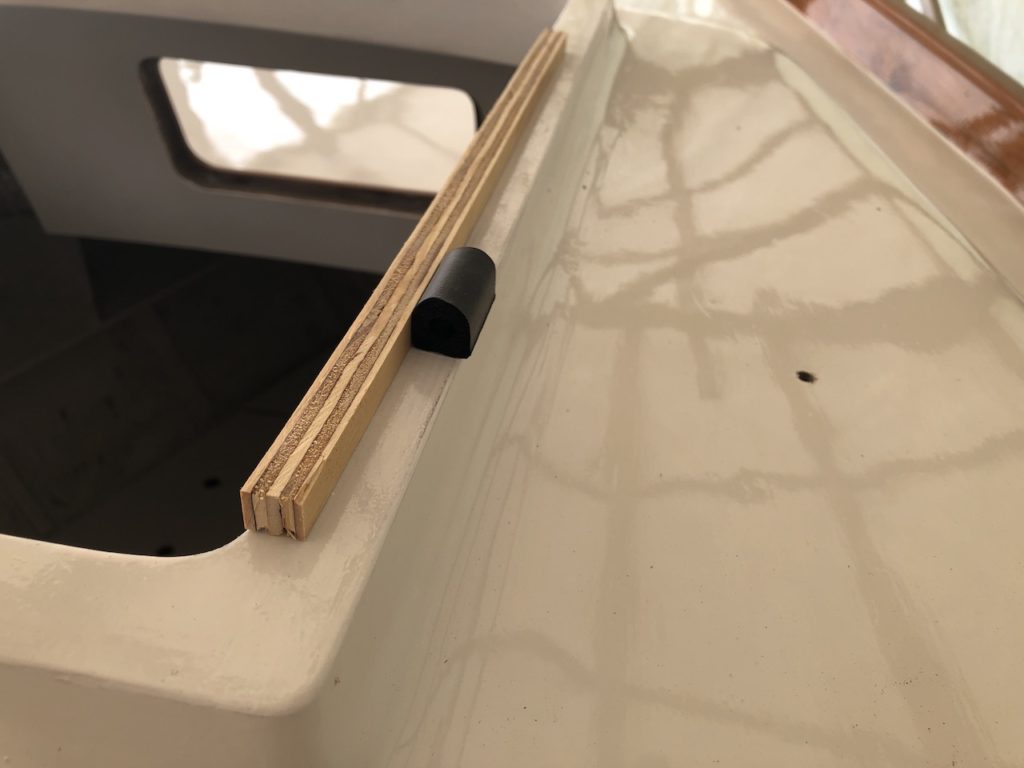

First, a few thoughts about hatches. The gasket material (a small piece of which you see below) has maximum efficacy when compressed by 25-50% of its height. I will fabricate a “lip” out off teak that will stop the hatch at from compressing the gasket more than a pre-determined amount. I decided that 3/8″ height from the top of the coaming was ideal, so I cut some 3/8-inch spacers out of scrap plywood.

With the spacers maintaining the hatch at the desired height, I dry-checked the hinges again and decide these hinges are simply too small for these heavy hatches.

Unable do find what I want anywhere online, I decided that custom-made hinges are required. I spent some time mocking up some samples.

More later on the hinges. The paint color in the cup below is “Rochelle Red”…

…it is for the inside of the cowl vents.

The cowl vents are now complete, so soon I will begin working on dorade box installations.

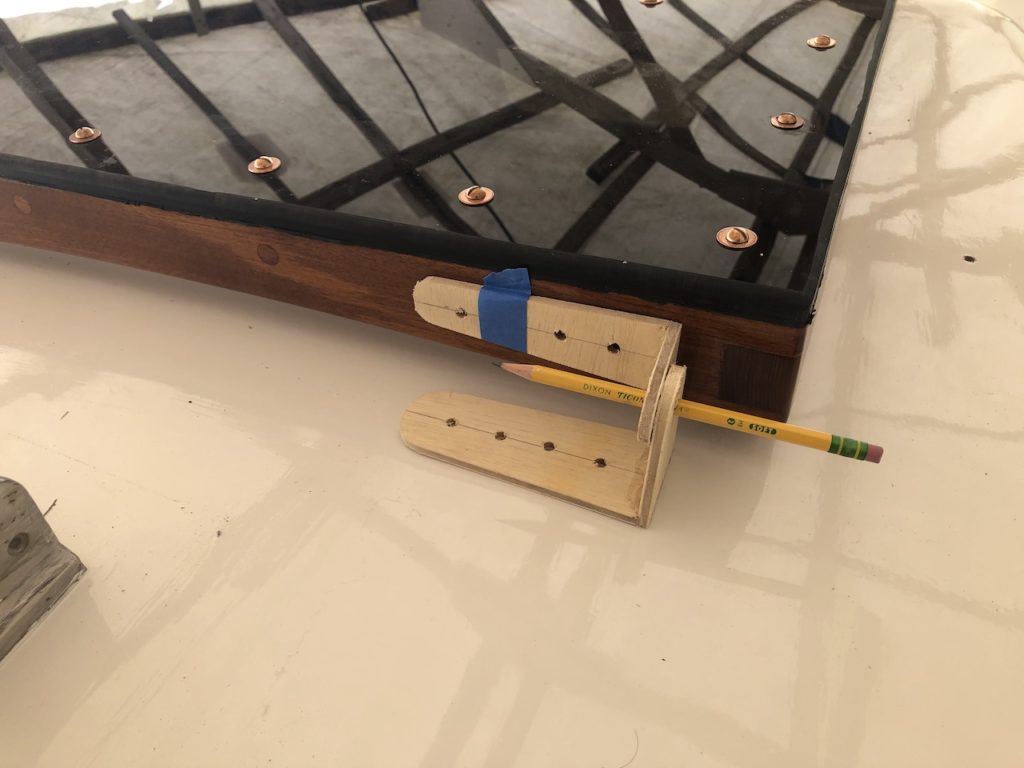

Speaking of paint, I’ve been working hard at finishing the interior painting while we still have warm days. As various parts of the interior receive final coats of paint, various other tasks become possible. One example, is that finishing painting the ceiling allowed me (and a helper) to install handrails on the cabin top. One of the challenges of this job is that all “pads” of a handrail must be coated with sealant (thickened epoxy) before the first bolt is driven up through the roof. The challenge is to keep the other pads from touching the roof and making a mess. I glued some old rubber gasket material to a few blocks and with these, and by moving them around, we were able to keep things relatively clean.

On the inside, I drive the bronze lag bolts with washers up through the teak backing strips.

After snugging them once, I waited a few minutes, then snugged again, then the inevitable squeeze-out clean up. Here’s the port/aft one-looper that sits just aft of a dorade box.

Here is the backing strip for the five-looper on the starboard side. Note the interior five-looper under the windows.

Starboard-side head compartment.

Port-side head compartment.

The five- and three-loopers follow the curve of the cabin sides.

The forward loops of the three-loopers straddle bulkheads.

Which is why there is just a single-bolt backing strip in the forward cabin.